Success Stories

Custom Ø60″ Butterfly Valve Seal

(Date Installed : 2012)

MANDATE

To replace a metal seal for Ø60” butterfly valve seal designed in 1949. Distortion, fatigue, and ovality issues prevented the proper sealing of sealing components. Actuation was designed for zero-friction and minimal interference load conditions.

DRC SOLUTION

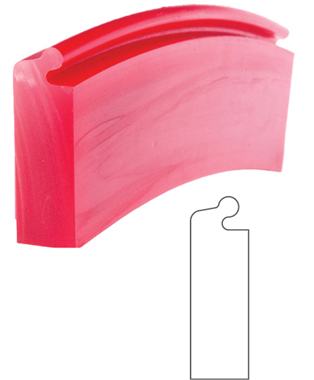

Using FEA and empirical techniques, DRC designed a bulb seal with a large deflection range able to bridge the non-concentric surfaces caused by distortion, fatigue, and ovality. The seal design required no material compression and water pressure elevated the compressive stress required for sealing. The frictional forces related to the seal deflection preload, were calculated to work within the operating limits for the actuator. Delthane85NSE was used for its excellent toughness, resilience and low coefficient of friction.

RESULTS

Leakage reduced to negligible levels and to the full satisfaction of the client.