High-performance polyurethane

elastomers for the hydroelectric industry

Hydroelectric Industry

Delta RIM Composites has been particularly active in the hydroelectric industry, producing custom seals for some of the biggest utility companies and turbine manufacturers in Europe and North America. Of interest to hydroelectric plant managers is the Delta RIM Composites composite 2 hardness j-seal used to seal dam gates. This seal is comprised of a thin abrasion resistant Delthane110E hard polyurethane shell, covering the bulb over 180°.

This shell serves to reduce the sliding friction when opening and closing the gate. The main sealing matrix is made of a much softer Delthane material having properties far superior to rubber in tear and tensile strength, compression set, ozone, UV resistance and brittle fracture. The chemical compatibility of the hard and soft polyurethane allows 100% bonding between the two materials and eliminates the handling problems usually associated with fluorocarbon clad rubber seals. In addition, these seals can be delivered in one assembled piece, to fit the given dam gate configuration, with or without the low friction Delthane110E cladding. This dual material technology has been extended to wicket gate seals and penstock seals as well.

Delta RIM Composites seals can be designed to meet specific load-deflection curves and can be molded in a variety of shapes, cross sections and radii of curvature.

About Us

Delta RIM Composites is a custom molding and engineering company capable of designing polyurethane parts, optimizing their design, building molds and production equipment.

Delta RIM Composites offers clients cost effective solutions for their polyurethane requirements.

Reasons to use Delthane seals

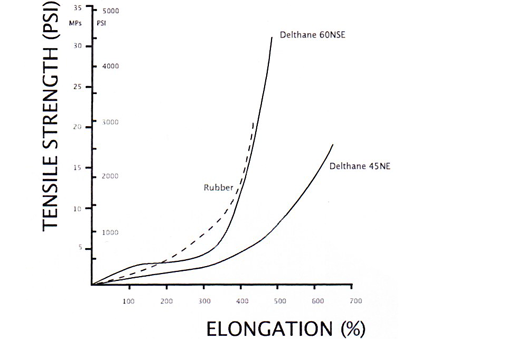

When compared to rubber, it can be seen that not only do polyurethanes offer superior mechanical properties, but exhibit load deflection curves more consistent with what is desired in a sealing application. The fluid-like behavior of the Delthane family of elastomers, as seen by the flatness of the tensile vs. elongation curves, explains the ease with which the Delthane deforms under load, allowing it to follow the contour of an adjoining surface, thereby securing a better seal. When compared with rubber at the 300% elongation point, it is clear that the Delthane family will provide a better seal at lower loads.